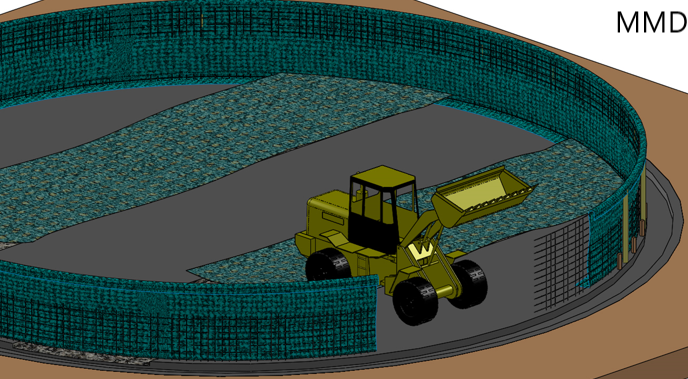

Mobile Dewatering Dams

The Mobile Dewatering Dam(MDD) can be cleaned out and re- used until project completion once constructed

The amount of geotextile material required will be on average 4 times cheaper than normal dewatering options currently being used, as the MMD’s material can be used 4 to 5 times before replacement is required.

Drying times for the sediment are 20% to 25% faster than normal dewatering bags due to effective open drying surface.

The required civil works area can be greatly reduced, since the dams can be used indefinitely and cleaned out on a regular basis.

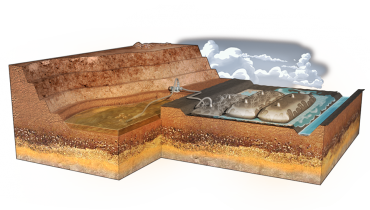

Geo Textile Dewatering

Geotextile Dewatering Tubes (also known as sludge tubes, geotubes, or dewatering tubes) are ideal for large dewatering or sludge removal projects. Geotextile tubes feature significantly larger dimensions and use higher strength woven geotextile fabric rather than the standard nonwoven fabric of Dewatering Bags.

The construction allows large amounts of sludge and silt to be easily removed without having to constantly change or replace bags. Due to their high strength and large capacity, dewatering tubes are used extensively in Wastewater Treatment Projects (WWTPs), agricultural ponds, aquaculture facilities, pulp and paper mills, and industrial lagoons. Geotube sizes can be custom made to your required location and surface area.

At Safeguard Equipment we understand the importance of dewatering and providing solutions that work. Our mine dewatering tubes are designed for dependable performance in dewatering mining tailings and mineral processing. The geotextile tubes are well made, durable, and are available in custom or standard sizes to suit your mine dewatering and mineral processing needs.